Ask AI on The Internet

Question: 1000 WORDS Determination of Iron or Copper using Flame atomic Spectrophotometer.INTEXT REFERENCE

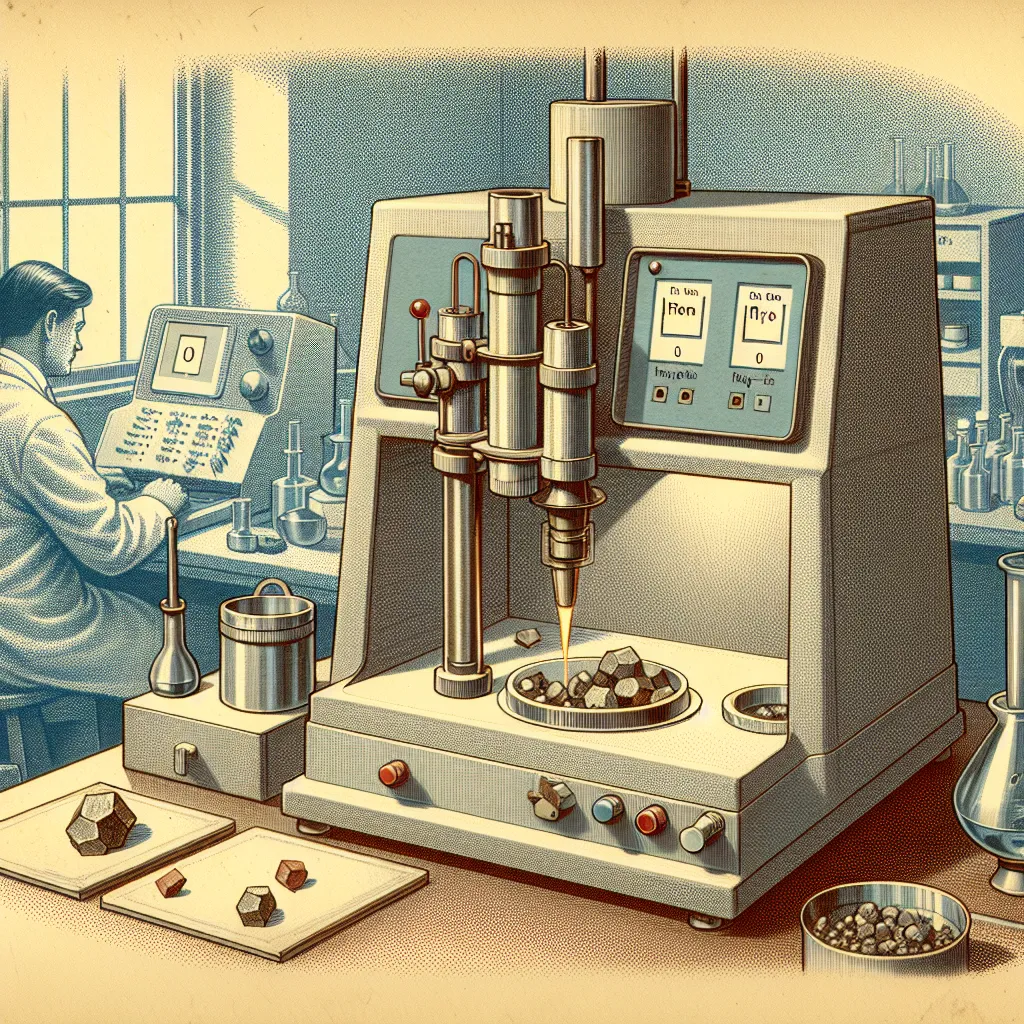

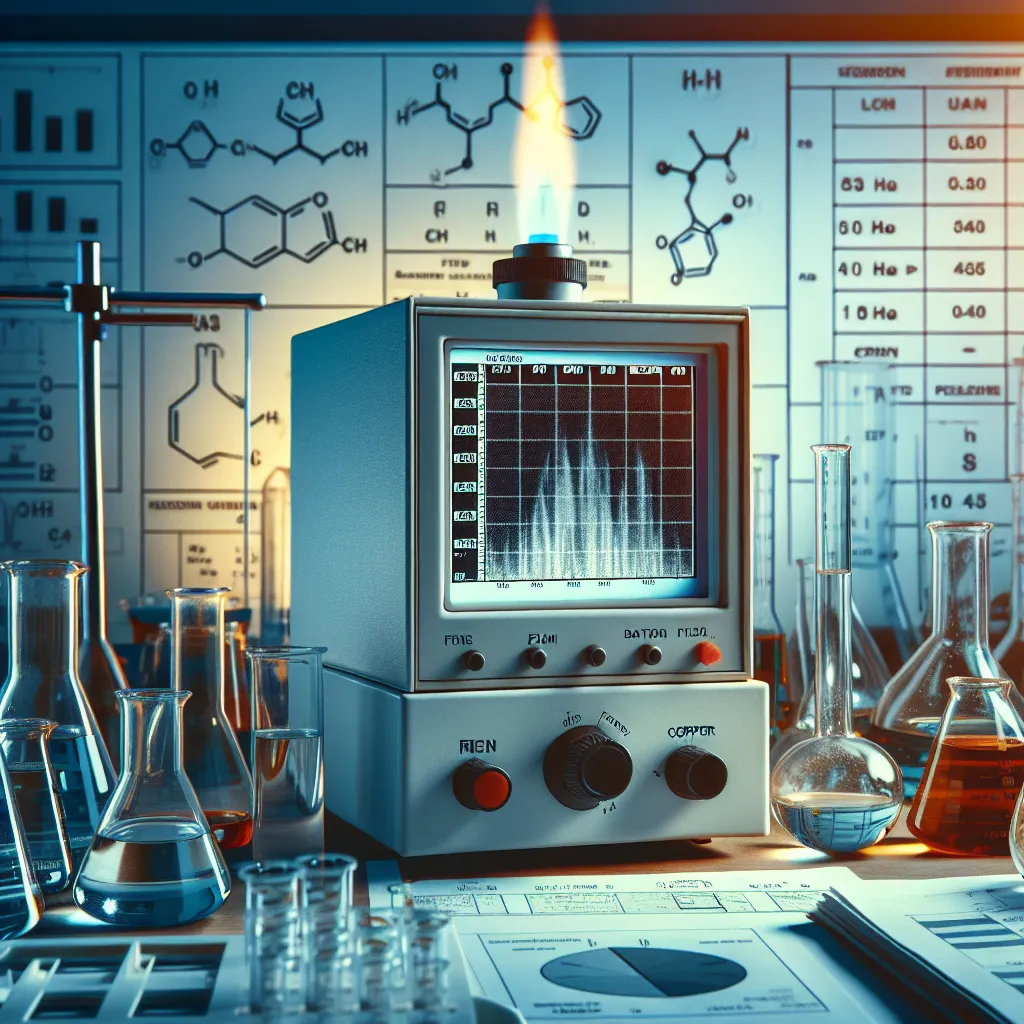

**Determination of Iron or Copper Using Flame Atomic Absorption Spectrophotometry (FAAS)** **Introduction** Flame Atomic Absorption Spectrophotometry (FAAS) is an analytical technique used to determine the concentration of specific metals within a sample by measuring the absorption of light at characteristic wavelengths. This method is particularly advantageous for metals such as iron (Fe) and copper (Cu) due to its sensitivity, precision, and simplicity in operation (Welz & Sperling, 2008). **Principle of FAAS** FAAS operates on the principle of atomic absorption where the sample is nebulized into a flame, and metal atoms are converted into their ground state. As these atoms absorb light from a hollow cathode lamp that emits specific wavelengths corresponding to the metal of interest, the amount of light absorbed is proportional to the concentration of that metal in the sample (Skoog, Holler, & Crouch, 2007). By measuring this absorption, one can quantify the amount of metal present. **Instrumentation** FAAS instrumentation comprises several key components including a source of radiation (usually a hollow cathode lamp specific to the element), an atomizer (typically a flame such as air-acetylene or nitrous oxide-acetylene), a monochromator to isolate the wavelength of interest, a detector to measure the intensity of the absorbed light, and a readout device for data processing (Christian, 2014). **Preparation of Standards and Samples** 1. **Preparation of Standard Solutions**: Accurate quantitative analysis requires the preparation of standard solutions with known concentrations of the metal ion. Stock solutions (usually 1000 mg/L) of iron or copper are first prepared using analytical-grade reagents and deionized water. Aliquots of this stock solution are then diluted to prepare a series of working standards covering the expected concentration range of the samples (Harris, 2010). 2. **Sample Preparation**: Samples, whether environmental, biological, or industrial, need to be brought into a solution form. This typically involves acid digestion using concentrated acids like nitric acid or hydrochloric acid and heating to break down the sample matrix and release the metal ions (Dean, 2005). After digestion, solutions are filtered and appropriately diluted to fall within the calibration range of the standard solutions. **Analytical Procedure** 1. **Instrument Calibration**: Before sample analysis, the FAAS instrument must be calibrated using the standard solutions. The calibration curve, which plots absorbance versus concentration, is generated. An ideal calibration curve shows a linear relationship confirming Beer-Lambert law within the working concentration range (Welz & Sperling, 2008). 2. **Sample Analysis**: Once the calibration curve is established, the prepared samples are nebulized into the flame. The instrument measures the absorbance at the specific wavelength for iron (typically 248.3 nm) or copper (324.8 nm) (Christian, 2014). 3. **Quality Control**: It is crucial to include quality control measures such as the analysis of blank samples (to correct for background absorption) and the use of certified reference materials to check the instrument's accuracy. Periodic recalibration and the analysis of duplicate samples can help ensure consistent results (Harris, 2010). **Data Interpretation** The concentration of the metal in the sample is determined by comparing its absorbance reading to the calibration curve. The result is often expressed in mg/L or µg/L depending on the sensitivity required (Dean, 2005). **Sources of Error** Potential sources of error in FAAS include spectral interferences (overlapping absorption lines), chemical interferences (formation of non-volatile compounds), and physical interferences (variations in nebulization). Careful method development, including the optimization of flame conditions and the use of matrix modifiers, can minimize these errors (Skoog, Holler, & Crouch, 2007). **Advantages and Limitations** **Advantages**: - High sensitivity and specificity for metals. - Rapid analysis and relatively simple operation. - Suitable for a wide range of sample types (environmental, industrial, biological). **Limitations**: - Only capable of analyzing one element at a time without reconfiguration. - Potential interference issues that require careful method optimization. - Requires careful sample preparation to avoid contamination and loss of the analyte (Welz & Sperling, 2008). **Applications** FAAS is widely used in various fields: - **Environmental Monitoring**: To assess the quality of water, soil, and air by determining trace metal concentrations (Dean, 2005). - **Clinical Diagnostics**: For measuring metal concentrations in biological fluids such as blood and urine (Skoog, Holler, & Crouch, 2007). - **Industrial Quality Control**: In processes such as metallurgy, where precise control of metal content is crucial (Christian, 2014). **Conclusion** Flame Atomic Absorption Spectrophotometry remains a cornerstone analytical technique for the determination of iron or copper, offering a robust balance of accuracy, precision, and ease of use. By adhering to proper sample preparation and analytical protocols, FAAS provides reliable data essential for research, diagnostics, and industrial applications. **References** - Christian, G. D. (2014). *Analytical Chemistry*. John Wiley & Sons. - Dean, J. A. (2005). *Analytical Chemistry Handbook*. McGraw-Hill. - Harris, D. C. (2010). *Quantitative Chemical Analysis*. W.H. Freeman and Company. - Skoog, D. A., Holler, F. J., & Crouch, S. R. (2007). *Principles of Instrumental Analysis*. Cengage Learning. - Welz, B., & Sperling, M. (2008). *Atomic Absorption Spectrometry*. Wiley-VCH.

Think your answer is better than the AI's? Post it below.

Question Tags

If you want your question answered by an AI, click here.

Post your own comment: